Dave Laubert of Defensive Creations is a name that may not be familiar to many, but if you appreciate the highest order of pistolsmithing, it should be. Dave is a pistolsmith in the most distinguished sense of the word. A member of the American Pistolsmiths’ Guild, he runs a one-man magic foundry out of Ohio. I met Dave through Pat Rogers, as Dave was the artisan behind the custom work on a number of Pat’s guns. At last year’s Friends of Pat Rogers memorial training event, Dave and I were talking guns.

Somehow, we got on the subject of K-Frames. I have a real weakness for vintage Smith & Wesson DA revolvers, so it’s hard to say how we got started, but I was all in. Dave mentioned he had picked up a couple of scrap Model 10s and 64s from a recent batch of police trade-ins with cracked forcing cones and other problems and that he had a notion to see what he could do with them.

As he threw out some of his ideas, I may or may not have begged shamelessly for a chance to see the final results. A few months later, I was able to spend a few weeks with a matched set of twin custom .38 Specials.

One of the least often encountered and most desirable K-Frames for both shooters and collectors is a three-inch-barreled round butt. That combination is truly the Glock 19 of the revolver world—much more concealable and handy on the belt than the standard four-inch square butt, while retaining a large measure of shootability. Good luck finding one.

Dave created a pair of highly custom round-butt three inchers with a raft of features that we will get to. But underneath the end results are two pieces of law enforcement history that Dave brought back from the inglorious fate of being scrapped. Tongue in cheek, he named the pair “the Spinny Twins.”

Table of Contents

CUSTOM WORK

The forcing cone is the little stub of barrel opening that sticks through the frame window and accepts the projectile being launched from the cylinder. If it cracks, the handgun is essentially dead. Dave removed the barrel, lopped off the offending portion of the cone, resized and rethreaded a “new” cone, and fit it back into the frame.

Reading that last sentence quickly may suggest that such an operation is quick, routine, or simple. No on all counts. It is far beyond the capabilities of the average smith.

Moving the barrel back moved the corresponding forward lug that the ejector rods latch into—one of two locking points on a Smith. Dave had to machine a corresponding amount off the lug. He then had to reshape and fit the locking surface. Since he had moved a locking point, Dave added a ball detent to the crane, adding a third locking point to reinforce the revolver for extra stability.

An S&W “triple lock” from the early 1900s is often considered the pinnacle of quality for the detailed fitting of that third lock in the frame, and Dave made these into mini triple locks with the addition of those detents.

Dave then cut the barrel back to three inches and machined flats on the sides of the heavy round profile. The wide rib got a dovetail cut for a fiber-optic front sight regulated to the rear notch. The end of the barrel received an aggressive reverse crown that creates a unique and striking look that makes the .38-caliber hole look closer to .50.

The overall effect of the work is a barrel that is half round/half octagon but not in the vintage rifle barrel style of one then the next—rather both at once. Photos can’t capture the overall effect in three dimensions of how striking the barrel is.

Rather than simply bob the hammer, Dave wanted to maintain a single-action capability while snag proofing the gun. He ground the hammer spur down to a very effective compromise between being able to access and cock the piece while giving very little material to hook onto anything in a draw.

He then put in the time and attention to smooth, hone, and tighten the action to a state of silky goodness. A double-action revolver’s action has two components—weight and smoothness. The shooter’s pressure on the trigger compresses the mainspring, rotating and locking the cylinder, and releasing the hammer.

Sometimes there are little hitches or variations in resistance as these actions occur, and the overall pressure required tends to be in the 12- to 14-pound range. When Laubert finished the twins, they were exact matches at 7.7 pounds of pressure to run the double-action with 100% reliability.

As remarkable as a reliable DA stroke that light is, the smoothness throughout the arc on both six guns is the real story. With triggers like these, you can hand the Smith to literally any shooter with confidence that they will be able to hit in DA mode.

The end results can be seen in the photos, but it is likely that the camera lens and ink on paper can’t fully capture the true depth. There is a symmetry and balance to these that makes you think you might just be an art lover. The attractive and functional satin finish on both guns is offset just so by the high polish and nitre blued screws.

The case hardening on the hammer and trigger of each is so gorgeous that more than one person I showed the twins off to just stopped and stared for a while. It’s like looking at a perfect sunset over the mountains, with vivid colors mingling and running. In a world of dull, flat Cerakote and polymer, these two are things of beauty.

Handling the two is an equally luxurious experience. It is everything familiar from handling a Smith & Wesson revolver, only with a precision that you can’t miss. The cylinder is released and rotates out and then back in with simultaneous smoothness and tightness that are testament to fitment.

Drawing the custom-shaped hammer back, the timing is perfect and the bolt locks into the cylinder smoothly while allowing no movement in any direction. The ability to make everything at once both silky smooth while firmly fitted and devoid of any play is the hallmark of a master craftsman.

Knowing that when these two were riding out the last of their law enforcement careers, they were likely scuffed-up, loose “beater” revolvers that were literally worn out gives their current state an extra measure of cool.

SHOOTING THE TWINS

All of the above are admirable and worthy, but the point of the exercise is to make not jewelry but a highly functional weapon. I spent a solid number of range sessions getting acquainted with the twins. I ran them across most of my normal battery of drills and several that are in development. I also did a lot of just rolling the triggers and enjoying hits.

I shot for groups on a rather windy day, so moved the target to 20 yards rather than the usual 25. The compact Ks shot nearly every load well and most had at least one group that cloverleafed all impacts. Dave had sent me a picture of his machine rest testing and he was getting close to an inch from the Ransom Rest—totally in line with what I was seeing from my hands.

Some range observations: The sights were excellent. The height and width of the front was perfect for the fixed notch in the rear, allowing an ideal amount of light to surround the blade. The green fiber optic made it impossible to not key on the front sight at speed.

The double-action trigger pulls were exceptional and made DA shooting simply shooting as opposed to the mental “more difficult, be careful” territory that most shooters approach revolvers from. I probably did 90+% of the shooting through the pair in DA.

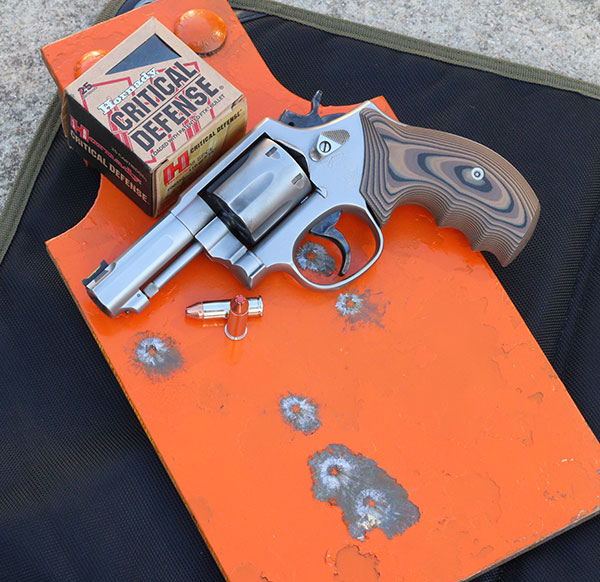

As an example, I had my smallish Defense Targets “Noner” target out at 40 yards and I was in a nice shady spot with a positive attitude. Rolling the trigger somewhat slowly on the stainless gun, I put six of the Hornady Critical Defense 110s onto the plate into about a six-inch group. I would take that with a long-barreled target revolver and be satisfied, but from a compact, I was solidly impressed.

On a later trip with the blued gun, I had a steel popper at 40 yards and wondered how the .38 would do support-hand only. A “weak-hand” DA shot would be about at the edge of my capability with most full-size revolvers with probably a 50/50 hit-miss ratio. The trigger on the Defensive Creations K was so smooth that my first attempt rang steel with four out of five Magtech semi wadcutters—and I called the one miss just barely off the edge!

The trigger cycles so oily smooth that it is really no trick to keeping the front sight in the notch throughout the arc even with only the support hand rolling it. Rolling the trigger at a moderate tempo, stacking hits into the center of playing cards was easy money at ten yards. Backing off to 25 yards, I was able to clean the plate rack firing 125-grain +P Gold Dots at a similar tempo. The twins may carry somewhat like snubnoses, but they shoot better than many full-size wheelies.

Although conveniently carry sized, the steel frames on the twins coupled with the VZ Grips helped tame recoil. From five yards, I lined up on the four-inch full value area inside the head of an IDPA target. Going aggressively from the ready, I rolled off five of the Black Hills 148s as fast as I could see that green fiber dancing. All five punched cardboard out of the circle in just 1.59 seconds.

FINAL THOUGHTS

To be clear, there are plenty of options on the market to carry more rounds, launch more muzzle energy, or fit in a pocket. A custom steel revolver in 2018 isn’t necessarily for everyone. But somehow I suspect that whoever ends up with either of these will appreciate what they are quite strongly and not worry a bit about what they aren’t.

Dave began this particular project simply seeing what was possible and playing with his vision of an ideal carry revolver. I am glad he did and wouldn’t be surprised if the twins spark a mini-renaissance in custom fighting wheelguns.

SOURCES

DEFENSIVE CREATIONS

(330) 823-6906

www.defensivecreations.com

BLACK HILLS AMMUNITION

(605) 348-5150

www.black-hills.com

HORNADY MFG. CO.

(800) 338-3220

www.hornady.com

MAGTECH

(763) 235-4000

www.magtechammunition.com

PERFORMANCE, BLUED MODEL 10 GROUPS

| LOAD | SMALLEST (inches) | AVERAGE (inches) |

| Black Hills 148-gr. wadcutter | 1.30 | 1.40 |

| Black Hills 100-gr. +P HoneyBadger | 1.40 | 1.70 |

| Hornady 125-gr. American Gunner | 1.20 | 1.45 |

PERFORMANCE, STAINLESS MODEL 64 GROUPS

| LOAD | SMALLEST (inches) | AVERAGE (inches) |

| Black Hills 148-gr. wadcutter | 1.05 | 1.45 |

| Hornady 110-gr. Critical Defense | 1.77 | 2.03 |

| MagTech 158-gr. LSWC | 1.60 | 1.79 |