The name of the sword from Arthurian legend conjures up images of knights at a round table, noble quests, great battles and saving damsels in distress.

While today’s warrior uses modern firearms, he can still have an Excalibur.

The modern Excalibur is made by SLR15 Rifles, Inc., and is the sister rifle of the immensely popular Grail rifle manufactured by the same company.

Table of Contents

SLR15 RIFLES

SLR15 Rifles is a division of Defensive Edge Training and Consulting, Inc., operated by Greg “Sully” Sullivan. Sully is a full-time cop, former tactical unit member and top-tier instructor. I have taken both carbine and carbine armorer courses from him and can vouch for his abilities as an instructor.

Having seen rifles from many manufacturers in classes over the years— as well as using them on duty—Sully knows what works and what doesn’t. Seeing rifles that were lacking in many areas is what prompted him to found SLR15 Rifles, Inc. The carbines built by Sully meet milspec and then some.

Besides being built by someone who actually takes AR-type carbines in harm’s way, another thing that sets SLR15 Rifles apart is that, when an order is placed, the carbine can be customized to the user’s preferences. This includes stocks, grips, sling mounts, flash hider, iron sights, etc.

EXCALIBUR

The Excalibur features a 16-inch barrel made of 4150 steel with a 1:8 twist, so it accurately fires both light and heavy .223/5.56mm loads. The barrel is chambered for 5.56mm NATO and “pushed” out a bit with a Michiguns camber reamer, allowing it to run more reliably when hot and dirty, especially with suppressors.

While SLR15 Rifles come standard with a chrome-lined barrel, my Excalibur came with a Melonite QPQ finished barrel. Melonite (the U.S. trade name for the Tenifer finish used on Glock pistols) is much more corrosion resistant than hard chrome or nickel. The Melonite QPQ process has a smooth black finish. Reportedly Melonite eases cleaning because fouling doesn’t stick to it like traditional chrome lining, and may increase accuracy as well as velocity.

Other options on my Excalibur included a Yankee Hill Phantom flash hider, ARMS 41 flip-up front sight, Troy Industries rear folding BattleSight, Precision Reflex carbon-fiber free-float handguard tube (the same as used on SLR15’s Grail rifle), Magpul CTR stock, Ergo Grip, BCMGUNFIGHTER ™ Charging Handle, CrossTac Single Point Sling Mount, and Sully Trigger Guard. It also included a single-stage trigger group and internal reliability upgrades on the bolt/carrier and trigger group.

RANGE EVALUATION

Before shooting the carbine, I ran a dry patch down the bore and properly lubricated the bolt. This was the total sum of cleaning and maintenance during the entire evaluation period.

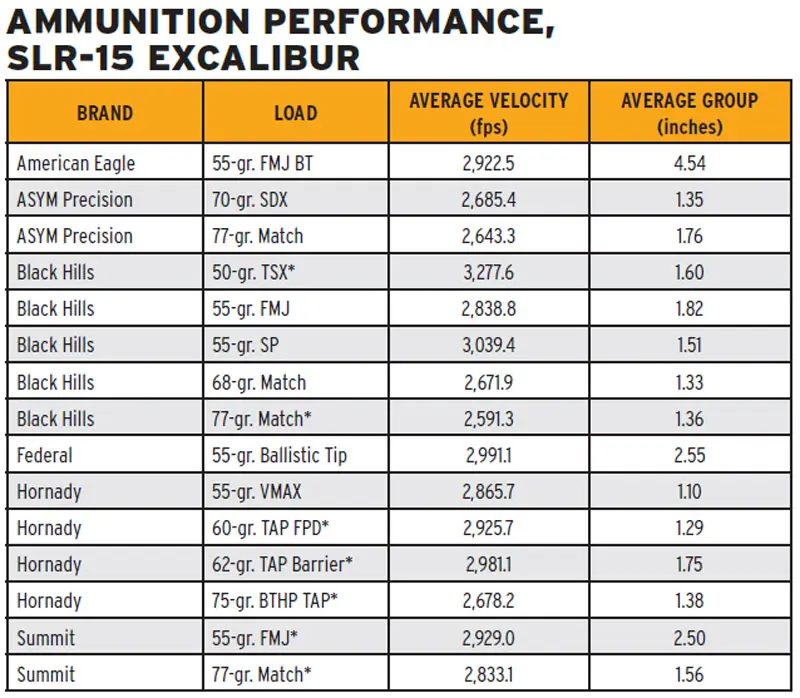

I took 15 different loads from five different manufacturers to the range for evaluation. The bullets ranged in weight from 50 to 77 grains and included both .223 Remington and 5.56mm NATO loads.

A common error when using a chronograph is to place the first skyscreen too close to the muzzle. The muzzle blast can easily result in false readings. To establish velocity of the loads, I used a PACT Professional chronograph with the start screen set 12 feet from the

muzzle. The results in the accompanying table were the average of ten-round strings.

Curious about the claims that Melonite may increase velocity, I compared the chronograph’s results with my notes from testing the SIG M400 (CONSTANT RANGE COMPANION: Three-Month SIG Sauer M400 Evaluation, January 2012 S.W.A.T.).

Across the board, the velocities of all loads were very close, but five of the 15 loads did show a slight increase. However, since the ambient air temperature was 17 degrees cooler when testing the Excalibur, and warmer ammo will increase velocity, the Melonite may indeed make a difference. Comparing a chromelined bore with the Melonite bore under identical conditions in the future may prove interesting.

For accuracy, I fired ten-round strings from the prone position using a 30-round magazine as a monopod, with iron sights from 50 yards.

SUREFIRE MAG5-60

After these initial tests, I loaded up a couple of SureFire’s new Mag5-60 60-round magazines to conduct some drills. While variances occur between carbines, the SureFire Mag5-60 magazines, loaded to capacity, inserted and locked up under a closed bolt in five different carbines, including the Excalibur. YMMV.

In all honesty, I doubt I would use the Mag5-60 in a carbine course, since one benefit of a class is manipulating the carbine, including loading and unloading. The SureFire mags put one in mind of what Confederate troops said about the Henry Rifle when it was introduced: “That damned Yankee rifle that they load on Sunday and shoot all week!”

Having said that, I found the carbine’s balance was better with the Mag5-60 than when using a side-mounted Redi- Mag with a spare 30-round mag, and having 60 stored kills is a good thing.

MALFUNCTION-FREE ZONE

After 600 rounds, I cleaned the Excalibur to verify claims that the Melonite finish reduces fouling in the barrel. There was no question as to the effectiveness of the finish this time. One patch saturated with SLiP2000 725 was run down the bore and allowed to soak in. After 20 minutes, it only took five or six dry patches before the patches came out clean.

I experienced no malfunctions with the Excalibur—not one. GI mags and those from Bravo Company, Lancer, Magpul and SureFire locked into place with an easy push/pull and dropped free with a press of the magazine release. The only thing I may replace is the CrossTac Single Point Sling Mount with a Tango- Down PR-4 Ambi QD Sling Mount.

I will definitely add an Aimpoint PRO red dot sight and SureFire Mini Scout Light, but other than that, the Excalibur is good to go. This one’s a keeper.

If King Arthur were alive today, I think he’d prefer this Excalibur to the original.