I was a member of SWAT for over 22 years and the U.S. military for many years. I have trained with, utilized, and carried suppressors as part of my employment. I was required to test, evaluate and select suppressors for purchase by my department and so I believe I have a pretty fair understanding of suppressors.

There is a global trend by citizens, police and military forces to purchase suppressors, and these customers are becoming more educated and sophisticated concerning them. This has led to innovation in emerging suppressor technology, which is focused on increased durability and improved performance life. The vast majority of suppressor purchases are by private citizens, as these devices are legal to own in most states and relatively easy to purchase. In several nations where I’ve worked, suppressors are commonly in use by the civil populations, which use them for hunting, leisure shooting activities, and to reduce noise pollution.

The U.S. military is rediscovering the usefulness of suppressors and is purchasing them for more general use by its forces. These devices are intended to reduce felt recoil, muzzle blast flash and sound. Overall the intent is to reduce the signature of the weapon and make its location difficult to establish during firing. Numerous units are currently deploying suppressors on crew-served as well as individual weapons.

Table of Contents

THE SUPPRESSOR MUST-LIST

When evaluating a suppressor, I have a few considerations:

- Product service life.

- Minimum blowback or backpressure.

- Proper function of host weapon with device attached.

- Ease of rapid attachment. Must be solid with no play once in place, each and every time.

- Consistent and predictable change of zero or preferably lack thereof.

- Reduction in sound signature, combined with the lowest possible first round “pop.” Typically the first round through a dry cold suppressor will be the loudest round fired. And regardless of some claims, this cannot be totally eliminated.

- Durability and toughness. It must take a beating and survive.

- Customer service. The manufacturer’s warranty and repair process.

- Flash reduction. Lowest possible light signature during firing.

- Size and weight. Should not be excessively long, bulky or heavy, obstruct the host weapon sights, or degrade the handling characteristics of the host weapon.

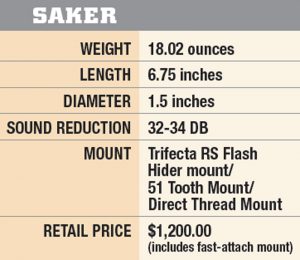

I recently visited Silencerco, LLC in Salt Lake City, Utah and spent five days testing their latest suppressor— the Saker.

THE SAKER

The Saker is specifically designed for a host of .223/5.56mm weapons. It is comprised of three basic components: MAAD (Multiple Accessory Attachment Device) mount, suppressor body, and interchangeable/replaceable front cap. The MAAD mount allows users to rapidly change to multiple types of commonly available weapon mounts. This modular system lets the user dictate the attachment system. The MAAD mount is versatile and attaches with ease.

The Saker is the first suppressor capable of attaching accessories without permanent modification. This allows for mission-specific uses and applications. Many times a purchaser is relegated to buying one product line due to lack of interchangeability with other mounts on their weapons. This issue is solved with the MAAD mount and the Saker. If you have a large inventory of weapons, you are no longer forced to change all the flash suppressors to facilitate mounting. For private citizens, this could result in a savings of several hundred dollars, while law enforcement or military forces stand to save significantly more.

The MAAD mount design facilitates one-handed attachment with rapid, uniform, and correct attachment every time. Both the front and rear sections of the suppressor body unscrew to allow access to internal components and attachment of new flash hiders and mounting devices. The MAAD mount is a non-regulated, non-controlled, multiple accessory mounting aperture. This means no additional tax stamp, and you can possess more than one and have them mounted on multiple weapons.

I must mention the Trifecta mount/ RS (Resonance Suppression) flash hider. This is one very useful and well thought-out piece of gear. It allows the user to rapidly mount the Saker onehanded onto the weapon, solidly with no play or slop. It is very clean, tight and precise. The Trifecta is going to give you the absolute best and most reliable fit with the Saker. Others will work, but this is a step up. It is a totally redesigned flash hider that, unlike other multipronged flash hiders, produces no audible “ring” when the weapon is fired.

Inside the suppressor body, the baffle stack is protected by an integrated initial shield called the Hoplon (named for the ancient Spartan battle shield). Silencerco changed the geometry of the face of the initial baffle, which is an inverted protective shield (Hoplon) to protect the remaining baffles. The Hoplon was designed to reduce wear from ballistic erosion and heat created by continuous firing.

Suppressors wear normally due to abrasion from firing, impact of unburnt powder, and heat within the baffle stack. This results in erosion that decreases capability and degrades performance. The Saker was designed to reduce metal fatigue and increase service life by utilizing specially selected metals in its construction. This metal mixture, borrowed from the aerospace industry, is new to suppressor construction. It has not been previously used due to the difficulty of manufacture related to its hardness. It is substantially harder (Silencerco claims at least 30% harder) than Inconel, a material commonly used to build suppressors. This allows for longer exposure to heat and results in reduced metal fatigue, thereby increasing the service life of the device.

The front cap of the suppressor is removable and can be instantly replaced when a projectile strike occurs. A front strike typically requires replacement of an entire device, because the front cap must be cut, replaced, and rewelded at the factory. Not so with the Saker, which only requires the user to unscrew the damaged piece by hand and replace it with a new cap.

DESTRUCTIVE TESTING

To prove the durability of their design, Silencerco subjected the Saker, along with seven other major competitors’ devices, to destructive testing. The test was conducted by using the same host weapon and ammunition for each suppressor.

With the suppressor attached, the weapon was fired in full auto continuously until the device either achieved baffle and front strike or blew off the end of the weapon. Of the seven devices compared to the Saker, the first failed at approximately 110 rounds. The final competitor’s device failed at 246 rounds. The Saker remained operative and functioning past 325 rounds fired, when the gas tube of the test weapon failed (melted from the heat).

Light levels are measured through a combination of high-speed photography, light meters, and temperaturesensitive photography. Even though there is currently no uniform industry standard of testing light emissions generated by muzzle flash, we tested the Saker suppressor on a ten-inch barreled AR both with and without a flash suppressor attached. All tests utilized the same ammunition.

With the Saker attached as compared to the M16A2-style flash hider alone, an 80% reduction in flash was noted. Obviously this is subjective based on the conclusions and opinions of the observer, comparison of still-frame photographs and video.

LABORATORY TESTING

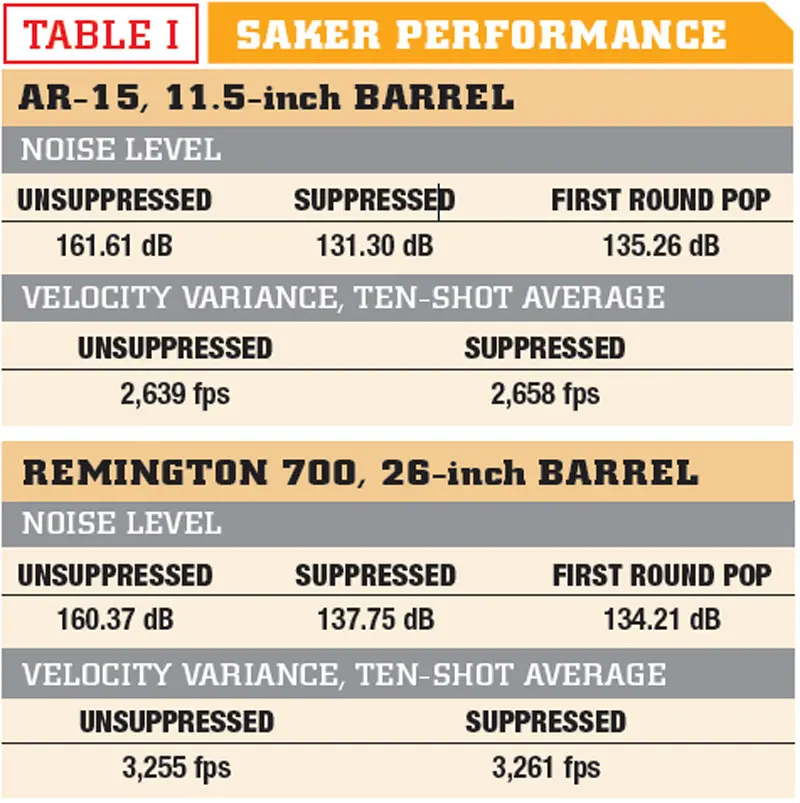

Our initial laboratory testing was conducted at Silencerco in an indoor range equipped with sophisticated soundmonitoring equipment. We utilized tenshot groups to test the sound suppression of the Saker and monitor the velocity changes with and without the suppressor attached. The results of the tests using two test weapons are in Table I.

FIELD TESTING

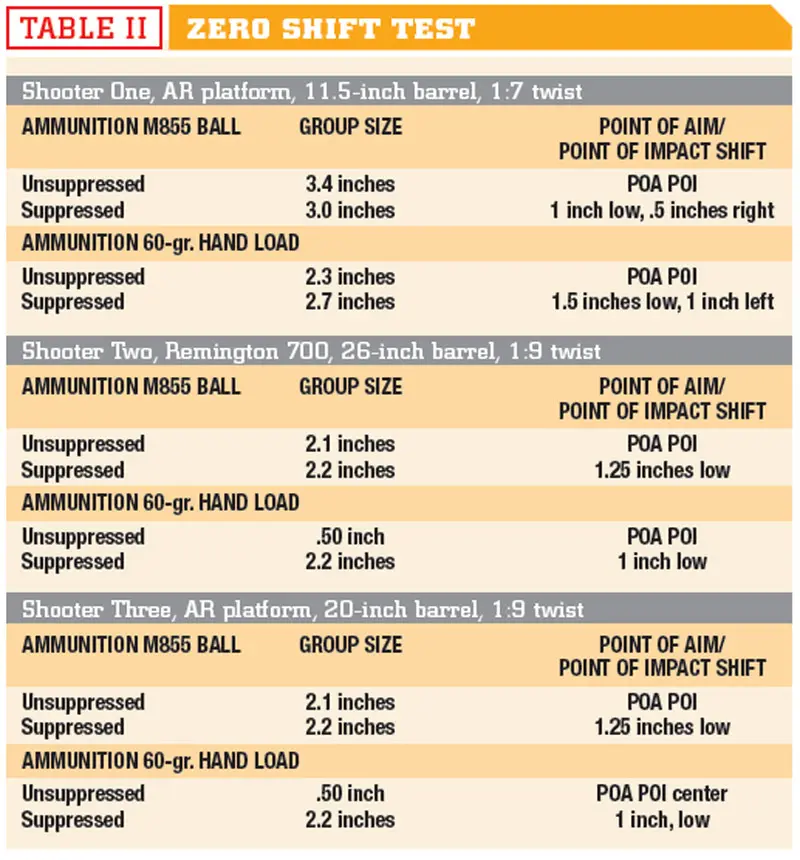

Almost all devices produce a zero shift when mounted. We moved to an outside range to continue testing the Saker and see how much zero shift was realized.

We utilized three different weapons and two different types of ammunition— M855 ball and a 60-grain handload. The objective was to determine the shift between point of aim and point of impact with and without the suppressor. All weapons were zeroed in the same environmental conditions without the suppressors prior to testing and re-zeroed when ammunition was changed.

Five-shot groups were fired with each weapon. The rifles were cleaned and allowed to cool for ten minutes between strings. Between suppressed shots, the Saker was removed and reattached prior to firing the next round. All weapons were benched and bagged for testing. Three different shooters were utilized during this testing, with each being assigned a weapon. The distance to target was 100 yards; wind speed zero; barometric pressure 25.10; temperature 55F; elevation 4,400 feet. The sky was overcast and it was hailing. The results of this test are in Table II.

CONCLUSIONS

Silencerco is a relatively new company that has been in business since 2007. It is owned and operated by Mike Pappas, Josh Waldron, and Jonathan Shults. The manufacturing plant is currently running 16 hours a day, seven days a week, to keep pace with demand. They are producing and shipping over 2,000 suppressors of various types monthly. This doesn’t include adapters, attachments, and accessories.

Silencerco LLC produces a muzzle brake and flash hider. Several other accessories are in development for this mount without the use of the suppressor. The Saker is a one-of-a-kind modular suppressor system that can be adapted and modified by the user as needed. It comes with a lifetime warranty. The product, however, is claimed to outlast the barrel of the host weapon under normal firing conditions. We’re not talking about continuous full-auto firing until the barrel melts—you still need to treat the suppressor like you would a rifle barrel.

Silencerco is highly focused on customer satisfaction and service. During my stay, I visited the customer service/ product repair department twice a day. I tracked 19 items during my five days there. All devices were repaired or replaced within four hours and on their way back to the client. Silencerco provides the client with a shipping code and return free of charge. Less than one percent of their total annual products sold are returned for repair. That in itself says a lot about their products.

Although the length and depth of testing I subjected this Saker to was short, I believe it was conclusive. Based on my experience and testing of this suppressor, I highly recommend it. The device exceeded my expectations and performed above standard. I was very impressed with the fit and finish, test results and overall package.

The Saker suppressor is intended for the educated professional and expert consumer. It is designed for those requiring quality and willing to pay for it. The Saker offers versatility and flexibility. I have seen only a handful of devices worldwide with comparable quality. The Saker is, in my opinion, one of the finest products of its type.