SIG Sauer is probably best known for their high-quality pistols. But lately the company has also been making news with AR-type rifles.

First came the SIG 516, which uses a unique short-stroke gas piston design. The latest AR to come out of SIG’s Exeter, New Hampshire factory is the M400.

Introduced at the 2011 NRA Show, the M400 uses the traditional direct gas impingement design. Still, this is not “just another” AR-type rifle.

I recently acquired an M400 for evaluation and was able to thoroughly test it over a period of three months.

GENERAL CHARACTERISTICS

The M400 comes standard with a lockable hard-sided plastic case, single 30-round magazine and the obligatory gun lock.

The chrome-lined 16-inch barrel has a 1:7 twist, which allows it to shoot heavier bullets with more precision while still allowing good accuracy with lighter bullets, and is fitted with an A2- type flash hider. The front sight assembly is the correct “F” marked unit for carbine-length barrels.

A removable A2-type carry handle/ rear sight assembly comes with the M400. The flat-top rail is 1913 Picatinny spec and is “T” marked.

The stock is of the six-position collapsible type, and the handguards have a heat shield. The M400 has an A2 pistol grip (more on this later).

The M400 has built-in sockets on both sides at the rear of the lower receiver for push-button swivels. These can be used as standalone swivels for a single-point sling, or with a two-point sling using the swivel under the front sight housing.

The magazine release on the M400 is ambidextrous, and there is a “fence” around the release on the left side of the carbine. The safety is not ambidextrous. The sides of the fence are square instead of rounded like most ARs. This does nothing for functionality, but does give the M400 a different look.

On the front of the magazine well are deep grooves that provide a good

grip for those who prefer to hold on to the mag well while shooting.

The M400 has a built-in tensioner between the upper and lower receivers. A captive spring in the lower pushes up on the rear takedown pin lug when it is locked in place.

This is the first time I have seen this type of tensioner to remove/reduce any play between the upper and lower. In the past I experimented with the Accu-Wedge and, while the product did reduce movement, I found no discernible difference in accuracy, and quite honestly any slight movement between the upper and lower does not bother me.

Some may really like this feature and others may simply not care one way or the other, but regardless it’s a nice touch on SIG’s part.

Out of curiosity, I removed the bolt carrier and took the extractor from the M400’s bolt. The insert in the extractor spring was the correct (black) insert for a carbine-length gun. Rifles use a blue-colored insert. The screws on the carrier key were also properly staked.

It’s nice to see SIG did their homework and went the extra mile to make sure the M400 is as reliable as possible.

M400 FIELD EVALUATION

The M400 was properly lubricated before the evaluation started, but it was not cleaned for the remainder of the test period.

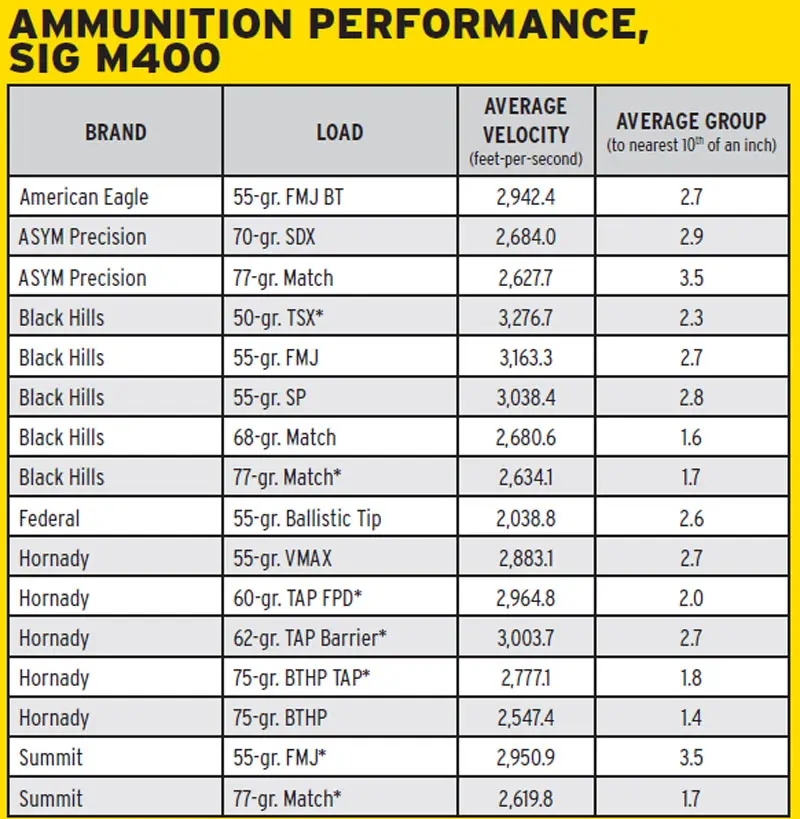

The first day I went to the range with 16 different loads from six manufacturers. Loads ranged from Black Hills 50-grain TSX and

American Eagle 55-grain FMJ BT to 75- and 77-grain loads from ASYM Precision, Black Hills, Hornady and Summit.

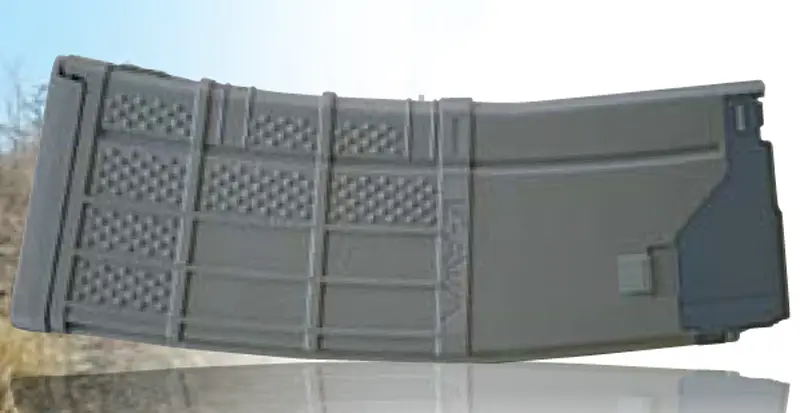

While I often use a variety of magazines to evaluate a new AR, to kill two birds with one stone, I took the opportunity to exclusively run the new Lancer Systems L5 Advanced Warfighter Magazines and see how they performed. The L5AWM is a hybrid magazine that uses a one-piece wrap-around hardened steel feed-lip assembly that is permanently attached to an impact-resistant polymer body. I’m happy to report the Lancer mags worked very reliably, and would not hesitate to carry them in a duty weapon.

Results of the tests are shown in the accompanying Ammunition Performance Table.

Considering the 1:7 twist, it came as no big surprise that the best groups were turned in with the loads using heavier bullets, with the tightest group produced with Black Hills 68-grain Match at 1.0 inches, though all the other heavy loads were right behind it within a few hundredths of an inch. The sole exception was ASYM Precision’s 77-grain load at 3.5 inches. I cannot explain this anomaly, as this load—in fact from the same lot—has produced tight groups in other rifles.

All loads were capable of making head shots at 50 yards should the situation demand it.

By the time I had finished firing the first 320 rounds in a relatively short time, the middle knuckle on my right social finger was beginning to develop a blister from the gap between the bottom of the trigger guard and the pistol grip.

This gap is no big deal if you plan on running a magazine or so through a gun every other weekend, but can become downright painful during a highround- count carbine course. Many shooters stick a foam earplug in the gap, but a better fix is something like Magpul’s MOE Trigger Guard.

In addition to my middle finger, the inside of my ring finger was becoming sore from the A2 pistol grip. Unless custom made for a single individual, bumps on pistol grips rarely fit most people and cause a poor grip. If I were to buy the M400, I would replace the horrible A2 grip with a TangoDown Battle Grip. And since the Battle Grip overlaps the aforementioned annoying gap, it would take care of the grip and gap at the same time.

After chronographing and shooting for accuracy with the issue sights, I mounted an Aimpoint PRO red dot sight (Always On, Always Ready, September 2011 S.W.A.T.) on the M400.

Whenever I went to the range over the next several months, the M400 went with me. My son Flint ran numerous drills with the M400, and grandson Austin also helped turn good ammo into empty brass.

Although the M400 did not show any signs of becoming sluggish, I reapplied lube to the bolt at about 500 rounds.

On one occasion, I was surprised when Danny Collier came to the range. Danny had recently returned from his second tour in Iraq with the 422 MP Company and was gracious enough to put a couple hundred rounds downrange with the M400. It was an honor to have one of our brave troops on my home range.

On that particular day, I also had the Kel-Tec KSG with me (SOMETHING NEW UNDER THE SUN? Kel-Tec KSG Shotgun, November 2011 S.W.A.T.). Danny, Flint and Austin took turns firing the KSG and the M400 while I kept busy loading the L5AWMs. At one point, I called a halt to shooting the M400 to let it cool down, because so many rounds had been fired through it in such a short period that I was concerned about a chambered round cooking off.

By the time the evaluation was over, an additional 780 rounds had been fired through the M400, for a total round count of 1,100. While not a tremendously high round count, I did not experience a single malfunction throughout the testing. The M400 chambered and extracted everything it was fed.

The SIG Sauer M400 is an accurate rifle and I have no reason to expect that the reliability it demonstrated would not continue for thousands more rounds. It is a quality piece worthy of the SIG name.