When I heard that Wilson Combat was building a 1911 to the specs of premier tactical trainer Ken Hackathorn, I recognized the ingredients for a great gun.

Ken Hackathorn’s background would take an article in itself to cover. He has been instructing for almost 40 years and has provided training to some of the most elite military and police units in the U.S. and around the world. He served as a weapons instructor in the U.S. Military and spent many years as an Ohio Deputy Sheriff, where he was on their SRT and was responsible for their training. Ken attended one of Jeff Cooper’s first public classes before the Colonel founded Gunsite, where Ken later came on board as an instructor. While Ken immensely respected the Colonel, he was also one never to stand still.

Ken is progressive rather than dogmatic and thus has significantly evolved his material since his Gunsite days, and continues to do so. This is one reason he became one of the most in-demand instructors of elite police units and Special Operations military units worldwide, including the German SEK, FBI Hostage Rescue Team, and the most elite U.S. Special Operations unit. Ken’s encyclopedic knowledge of firearms and training history alone is worth the price of any class he’s teaching, plus he’s written countless articles.

Right side of Hackathorn Special shows Wilson Combat logo, fore and aft slide serrations, and flutes on chamber area of barrel.

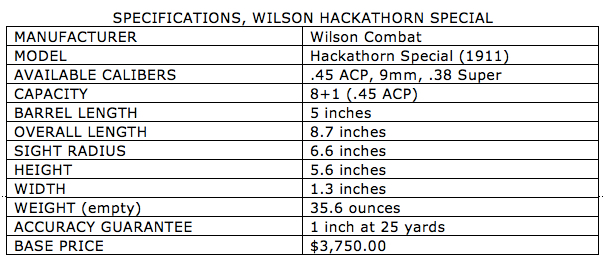

Wilson Combat is a custom 1911 manufacturer where a team of experienced gunsmiths hand builds each gun and hand fits all parts. In the quality control process, the gun must pass a series of detailed inspections. These take place prior to its final prep, after its final assembly, after being test fired, and finally before the gun is shipped out. This list encompasses over 70 items, and a written copy accompanies each gun.

The test-firing regimen includes over 50 rounds of mixed ball, hollow points and semi-wadcutters. Given this level of handcrafting and attention, delivery of a Wilson firearm may take a year from when it is first ordered.

Ken approached Bill Wilson about building a 1911 to his specs. Ken wanted a showpiece 1911 that would not sacrifice functionality and reliability. Bill Wilson liked the final project so much that he asked Ken if they could add it to their catalog. The end result is the Wilson Hackathorn Special.

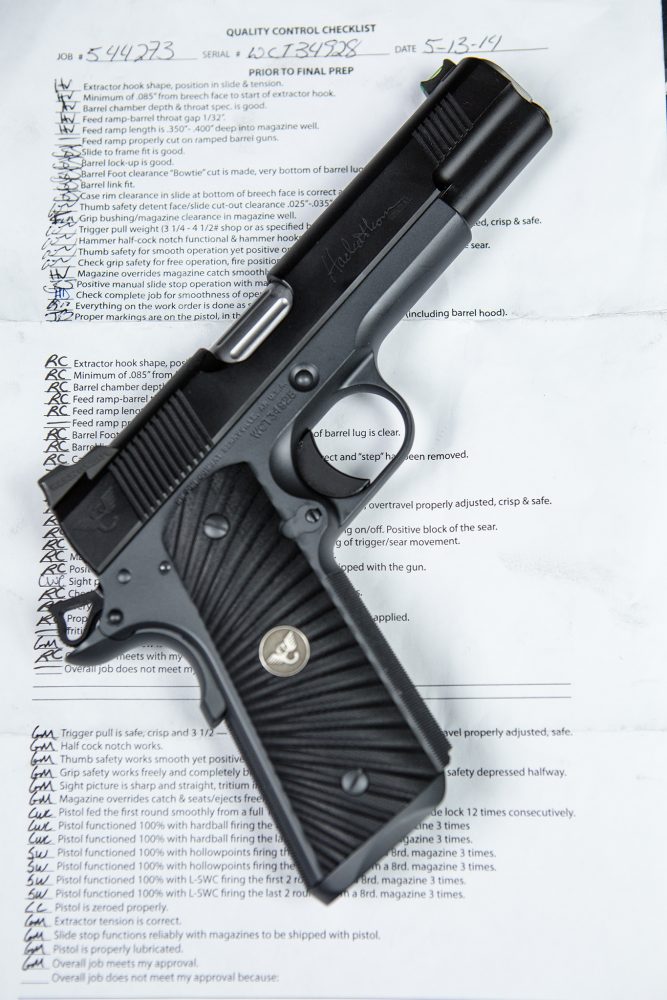

Test pistol was finished with black slide paired to a gray frame.

Table of Contents

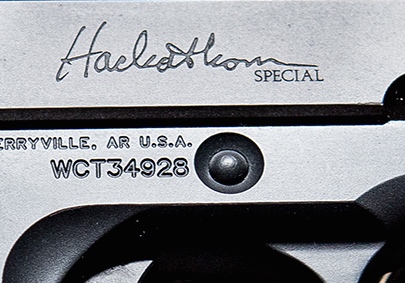

HACKATHORN SPECIAL

The Hackathorn Special is a full-sized carbon steel framed 1911. The slide comes with front and rear cocking serrations, characteristic of newer guns, while the front of the slide features ball end mill cuts, reminiscent of the first 1911s. Wilson Combat’s logo is on the right rear of the slide.

The bottom of the slide has heavy machine chamfering to minimize sharp edges. Its five-inch stainless match-grade barrel and bushing are hand fit and the exterior of the chamber area is fluted. The reverse crown is hand cut into the muzzle, which itself fits flush with the bushing. The slide lock hole is countersunk. The gun makes extensive use of Wilson Bulletproof parts, including their one-piece bulletproof magwell, magazine release, and thumb safety.

To make the gun fit the concealed carry mode better, Ken chose the Wilson Concealment Beavertail Grip Safety, which is a bit shorter and not as likely to print since it doesn’t protrude as much as a full-sized beavertail. This is paired with a shorter Commander-style rounded hammer. Ken selected a medium-length trigger to allow plenty of space for gloved use. The trigger on our sample broke at four pounds and was amazingly crisp.

The only available options on the Hackathorn Special are a blued finish, ambi safety, and choice of front sights. While Ken’s personal gun is blued, I went with the standard Armor-Tuff finish, which features a black slide paired to a gray frame. This finish works very well, as evidenced by the accompanying photos, which were taken after we had over 1,000 rounds through the Hackathorn Special.

Wilson sent me a stock Hackathorn Special for review, with the green fiber optic front sight that comes standard on this model. As soon as I picked the gun up, I appreciated how fast and naturally it centered in the rear sight, a Wilson Combat Battlesight that features a deep .145-inch U-shaped rear notch. Through it, the .125-inch wide front sight is very quick and easy to pick up. The rear sight blends well with the rear of the slide, which features 40 lines-per-inch (LPI) serrations. The top of the slide incorporates 30 LPI serrations that trace a path from the front sight to the rear.

Since my FFL dealer, Jackson Armory in Dallas, is a stocking Wilson dealer, I had the chance to compare the Hackathorn Special to several other Wilson offerings and appreciate its features.

I compared my pistol’s green fiber optic front sight to a gold bead impregnated front blade—the way Ken has his set up. The store manager had me step into a slightly darkened room to illustrate that the gold bead is more visible in some lighting conditions than either the fiber optic or a tritium sight. The tritium needs darkness to really stand out.

The gun was somewhat tight when it arrived from the factory. Normally the first thing I do upon receiving a new gun is completely field strip it, remove any factory preservatives, and apply lubrication. But Wilson Combat ships their handguns well-lubricated and ready to go.

FUNCTION TEST

The Wilson instruction manual suggests firing 300 to 500 rounds through the gun before initial disassembly. I followed this course with the gun spread out over several range sessions using a variety of ammo in the Wilson eight-round ETM magazines that came with it.

As soon as I fired the Hackathorn Special, I realized that the 30 LPI checkering on the front strap of the frame and mainspring housing were perfect for me. I’ve fired other 1911s with the coarser 20 LPI checkering and found them to be uncomfortable to grip tightly and painful to shoot. I’ve typically had to outfit those guns with wraparound neoprene grips that cover the front grip’s checkering to make the gun shootable for extended periods with bare hands. I encountered none of this discomfort with the Wilson after hundreds of rounds fired. The black G10 Starburst stocks that the gun comes outfitted with provide a perfect grip without sacrificing comfort.

Wilson guarantees this gun to be capable of putting five shots of quality ammo into an inch at 25 yards when fired from a Ransom Rest. Since I didn’t have a Ransom Rest, the closest thing I could do was call on my friend Wayne Dobbs of Hardwired Tactical Shooting.

While I could never coax more than two inches out of the gun, Wayne had no trouble breaking the one-inch barrier. The gun had a preference for 230-grain loads, with the 230-grain Federal HST JHP proving to be the most accurate.

MALFUNCTIONS

While Wayne was firing, we encountered the first malfunction. With not quite 500 rounds through the gun, we encountered a failure to extract with the last round in the magazine, and the extractor dragged the empty case back into the magazine’s feed lips. After experiencing this, we performed a function test where the gun was fired with only a round in the chamber and the magazine removed. Ken Hackathorn devised this function test decades ago, though he considers it so obvious that he wouldn’t be surprised if someone thought of it before him.

The test serves to isolate the extractor function and spotlight 1911s whose extractors do not consistently hang onto the fired case until it reaches the ejector. The presence of a loaded or unloaded magazine in the gun provides support beneath the fired case until it reaches the ejector. Firing the gun without a magazine removes this support.

This test is especially useful when dealing with a 1911 that is exhibiting erratic behavior. If the gun fails to properly extract the round without a magazine present, it’s a sign of marginal extractor tension that is likely to get worse as more rounds are fired through it.

Hackathorn Special fieldstripped with magazine.

We set the gun up by inserting a magazine, chambering a round, and removing the magazine for each shot. (Dropping a round directly into the chamber and then letting the slide close produces undue wear on the extractor.)

During this test, we encountered several instances where the gun failed to extract the empty case, resulting in a stovepipe. Sometimes the empty case wound up between the ramp and breechface. Other times it dropped down the magazine well. Further, without the magazine in the gun, the cases that did eject, ejected in an erratic pattern.

I brought the gun home, disassembled, cleaned and lubed it, then brought it back to the range. We repeated the test and encountered similar results regardless of what brand of ammo we used.

We removed the slide from the frame, visually inspected the extractor, slipped a live round in, and rotated the slide. The extractor seemed fine. We reassembled the gun and repeated the test without the shock-buff and the gun performed no better.

So back to Wilson the gun went, where they adjusted the extractor and quickly got it back to us. This time it passed the function test with the magazine removed with flying colors, and we put another 500 rounds through the gun over several shooting sessions.

Rear sight blends well with rear of slide, which features 40 LPI serrations.

FAILURE TO FEED

During this phase of testing, we encountered a single failure to feed on the last round of a magazine. The round in question was a Federal 230-grain HST, which has a fairly wide-mouthed hollow point with a short overall length. We had fired nearly two boxes of this ammo without an issue before this malfunction popped up. This underscores the importance of firing a few hundred rounds of the load you intend to use for defensive purposes, and with the magazines you intend to carry.

This is especially crucial with the 1911, since the gun was originally designed to function only with FMJ ammo. Though Wilson 1911s are throated and the feed ramp and chamber are polished with a geometry to maximize feeding reliability, some hollow points represent too much of a challenge to offer the type of reliable functioning required for defensive use.

I set the Federal HST aside and fired an additional 300-plus rounds of mixed ammo without encountering any further issues. We had better luck with the Black Hills Tac-XP +P. We put over 100 problem-free rounds of this ammo through the pistol. This load uses a Barnes 185-grain all-copper hollow point with a deep cavity and thin walls. Since copper is one-third lighter than lead, it results in a longer, narrower profile than the Federal HST load.

Hole for slide lock is countersunk.

SUMMARY

While testing the gun, we fired well over 1,000 rounds of mixed ammo and encountered only two malfunctions under normal shooting conditions. Keeping in mind that other than lubrication, the gun was only cleaned once at around the 500-round mark, this isn’t bad at all.

Bill Wilson started his business as a one-man shop built on the cornerstones of quality work and customer satisfaction at all costs. Over the years, he has expanded to become the largest manufacturer of custom 1911s, and done so without sacrificing his founding principles.

The Hackathorn Special exhibits a level of quality that would make anyone proud to own it.

SOURCES

WILSON COMBAT

(800) 955-4856

www.wilsoncombat.com

BLACK HILLS AMMUNITION

(605) 348-5150

www.black-hills.com

FEDERAL PREMIUM AMMUNITION

(800) 379-1732

www.federalpremium.com

KEN HACKATHORN

(757) 215-1959

www.aliastraining.com

HARDWIRED TACTICAL SHOOTING

www.hardwiredtacticalshooting.com

JACKSON ARMORY

(214) 363-2767

www.jacksonarmory.com