This year marks the 20th anniversary the Special Operations Peculiar Modification (SOPMOD) program has been in use with U.S. Army Special Forces (SF).

I carried and used a SOPMOD-equipped M4A1 carbine during my entire SF career. One thing is for sure—the M4A1 carbine I carried my last combat tour (fall of 2015, Afghanistan) was on a whole other level performance-wise than the one I carried during my first SF combat deployment, the 2003 invasion of Iraq.

[Author’s Note: SF is not to be confused with SOF, Special Operations Forces, which refers to all the special units within all branches of the military (Army Rangers, Navy SEALs, etc). I will also refer to most SOPMOD items the way they are popularly known on SF teams, by their commercial names as opposed to their formal designations. For example, the SU-231 is simply referred to as an “EOTech” regardless of the generation or model.]

To best explain how influential the SOPMOD program has been at giving our warfighters a lethal edge over the enemy, I’d like to share my experience with the SOPMOD, specifically how the various generations (blocks) of items performed during my six combat tours in Iraq and Afghanistan.

Table of Contents

SOPMOD: THE EARLY YEARS

By the time I made it to my first Special Forces ODA in the fall of 1998, the M4A1 was in service with SOF and the first issue of SOPMOD equipment (Block I) was already into its second year of implementation. In fact, Operators had already identified two items in the Block I kit that had issues.

The first item, the tritium-powered Trijicon Reflex Sight, was very dim and hard to see, not the ideal optic for the fast, quick-aim shooting required for CQB. The Army already had good working red dot optics in the inventory. The Rangers and a few other select Special Operations Forces (SOF) units had been using various Aimpoint red dot optics since the early 1990s.

About the same time SOPMOD had decided to go with the Trijicon Reflex Sight, the conventional Army was in the process of selecting the Aimpoint Comp M2 (designated the M68 CCO Close Combat Optic) as the first red dot optic for general issue to all combat troops.

When deciding on which piece of equipment fulfills a requirement the best, the conventional Army and Special Forces often choose differently.

The second item, the Visual Light Illuminator (VLI), had an absurdly short battery life (less than an hour). And while listed as able to produce 90 to 110 lumens at best, it put out a very dismal 90 lumens (too weak a beam for CQB work). Lastly, the plastic body of the light was prone to breaking somewhat easily.

A year later in 1999, we saw the first phased upgrades for SOPMOD with the replacement of these two items with the Aimpoint Comp M2 and a SureFire model M951 weaponlight. Thankfully SF got on board with the big Army and adopted the M68, not because it had passed some special trial by Operators, but solely for the reason that all combat units were getting issued it. Basically it was just good timing for SF—when issues were noted with the Trijicon Reflex Sight, the Aimpoint Comp M2 was already on its way.

As it turned out, 1999 was a very busy year for the SOPMOD program. The SOCOM heavy-profile barrel was adopted for all SOF M4A1s. Also enough Knight’s Armament suppressor-capable flash hiders had finally arrived to outfit every carbine in the unit, even though the Knight’s suppressors had been issued back in 1997. Until that point, enough for only about half the carbines were available.

CRANE SOPMOD MANUAL

The Crane SOPMOD manual was also published that year. Along with technical data and instructions on how to properly zero and operate the various SOPMOD items, the SOPMOD manual was the first to offer advanced M4 engagement techniques and ballistic information—well beyond the shooting techniques covered in the Army Marksmanship manual FM23-9.

It’s not that the manual showed anything new to SOF. It’s just that before the SOPMOD manual, if you wanted to learn these techniques, the only way was from your teammates during range training or from a specialized shooting course. Now for the first time, one manual covered these same techniques in detail.

If you have never seen or read it, I highly recommend trying to get one in print or online. While the equipment information is dated, as it covers the first SOPMOD items circa 1997, the methods and data for shooting distance and moving targets with red dots are still relevant today. In fact, I believe that only the latest edition of the Army Marksmanship manual (now TC 3-22.9), released in the summer of 2016, contains the same amount of shooting techniques and methods as the 17-year-old SOPMOD manual does.

Going into the year 2000, one item that has become standard on most ARs for the last dozen years or so came about at this time, and in a surprising way. It was not some pre-planned upgrade but instead was developed in response to a malfunction existing in a bad batch of M4A1s that our unit had received. The fix for these carbines would lead to the creation of an item.

ALL HAIL THE O-RING!

During the spring of 2000, the first issue of M4A1s had already hit the end of their operational life span at five years old, and they were being replaced with brand new ones. Almost immediately we started to experience failures to extract with several of the newly issued M4s.

As soon as word went up the chain of command that there was a common issue with the new carbines, the response from the manufacturer was pretty damn good.

Within a month, Colt Mfg. had a team at our unit to inspect and test every newly issued carbine, whether it was having problems or not. All troubled carbines were replaced immediately. The problem was later identified as, during the chrome-lining process of the chamber and bore of the M4 barrels, the chrome lining was too thick on some, resulting in too tight chamber areas, which led to the failures to extract during firing.

It was also determined that if the M4 extractor had a little extra tension behind it, it would still have been able to extract spent cases correctly, even with these flawed barrels. Additionally, the extra gripping force of an enhanced extractor spring did a much better job pulling a spent cartridge out of an extremely dirty chamber, allowing the M4 carbine to remain running longer under dirty conditions without cleaning.

So with this data, the techs at Crane developed the Reliability Parts Set, which consisted of three items: a fivecoil extractor spring; a slightly lengthened blue rubber insert, which was also changed to black for easy identification; and a rubber O-ring to go around the extractor spring to provide a little extra power.

I do not remember these kits making it in time for the 2000/2001 invasion of Afghanistan, but by the 2003 invasion of Iraq, they were plentiful in the unit.

Since then, the Crane Reliability Parts Set with the O-ring has become standard issue on both the M4A1 and the MK18 shorty uppers. It was not until 2012 that I saw the first upgrade to the O-ring on a military M4, with Colt’s newest extractor spring. Although it has fewer coils than the enhanced SOPMOD spring, the coils are significantly thicker, providing so much spring tension that an O-ring is not needed.

If you purchased an AR made by Colt in the last couple years, you have this newer spring. Aside from the thicker coils, it can be identified by its bronze color. If you just have a silver extractor spring, regardless of the make of the AR, ensure it has a rubber O-ring around it. The added power this little rubber ring provides greatly decreases the potential for extraction problems, especially with a dirty gun.

SOPMOD GOES TO WAR

For both the 2001 invasion of Afghanistan and the 2003 invasion of Iraq, the same SOPMOD Block I items first issued in 1997 were what was primarily available to use. Although I did not participate in the invasion of Afghanistan, I did take part in the 2003 invasion of Iraq, with my assigned task to push north from Kuwait, with the mission of getting into Baghdad.

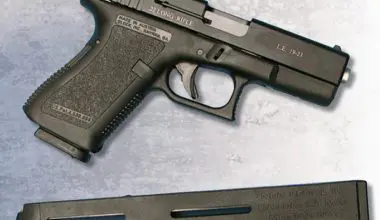

Because a lot of us expected urban engagements and CQB—with the exception of the teams tasked to operate in the open desert—the set-up of choice for many of us was the M4A1 with Aimpoint M68.

My M4 was outfitted with all the available SOPMOD accessories of the time: a Knight’s RAS rail (first generation with the tightening screw by the front sight post), SureFire M951 light, PEQ-2 IR laser, and Knight’s Armament vertical grip. I would use this same set-up for my second tour in Iraq in 2004.

All the SOPMOD items worked well, though twice I lost my zero with the M68 from dropping it on concrete. Over the course of the 50-plus raids I took part in, on two different missions I tripped and fell down on paved streets. Each time my rifle hit the ground hard and, while the lens and body of the Aimpoint were not damaged, the zero was completely thrown off.

One item that drew a lot of criticism during this time was the Knight’s Armament vertical grip. Commonly referred to as the “Ghetto Grip” or “Broom Stick,” it had a tendency to come loose if you did not tighten it enough. There were also reports of them snapping off in the heat of battle from the tight grips of soldiers under stress.

Aside from it perhaps being a bit too long, personally I never had a problem with the Knight’s vertical grip. As long as I tightened it with a screwdriver, it stayed pretty firmly attached to the rail. In fact, it was not until about 2008, when I got my hands on a Magpul AFG (Angled Fore Grip), that I stopped using the Knight’s grip.

WHERE’S THE EOTECH?

I have not mentioned the use of EOTechs (SU-231) because, although some teams within SF and SOF were using EOTechs as early as 2001,

my team was not issued them until early 2005 (Model 552) just prior to my third Iraq deployment. This brings to light the issue of the time lapse between when something is adopted under SOPMOD and when it actually is issued to all SOF.

Because SOPMOD is used by all of Special Operations, which equals thousands of operators from all four major branches of the military, it can take a significant amount of time (usually a couple years) to get a piece of gear out to all units.

Another example of how long it can take to get fully implemented SOF-wide is the MK18 10.3 upper. Although the front sight post version was widely used by SEALs since the early Iraq days, I did not see one until 2010, and by then it was the newer (current issue) low-profile gas block version.

Back to the EOTech.

Demand grew for these within the teams because of one issue we had with the Aimpoint M68. The dot of the M68 at 4 MOA was great for CQB shooting, but when aiming at a target 300 meters away, the dot

appears as a 12-inch circle. Workable at that range, but any distance past 300, the dot appears too large and often obscures what you’re trying to aim at in the first place.

The center dot of the EOTech is only 1 MOA and appears as a three-inch dot at a 300-meter target. The smaller dot allows for a precise point of aim or hold offs out to about 500 meters. Combined with the outer ring for quick aiming at CQB distance, many find the EOTech makes a great all-around optic.

But the only option was the fixed-power ACOG without a piggy-backed mini red dot. Those did not hit most units until 2005.

Once my team had them, I too made the switch from an M68 to an EOTech, but when I used one in an actual firefight, I realized I was better with the older M68. During training, I had no problem focusing on the EOTech’s smaller center dot and getting easy hits on sixinch plates at distance and such. But the first time I used an EOTech in combat, all I remember is seeing a red blur as I aimed at the threats.

The outer ring of the EOTech sight, designed to facilitate quick-aim shooting up close, totally distracted me from finding the small center dot, making it rather difficult to place it where I needed to on target. In the stress of the fight, the EOTech’s design was just too busy for me. I work best with the single dot of the Aimpoint.

ADDITIONAL ACCESSORIES

Other items that came out during the early war days were H&K steel 5.56mm magazines, the Gas Buster Charging handle (2004), and the Crane SOPMOD buttstock produced by Lewis Machine & Tool. I did not get a Crane stock until after my last tour in Iraq in early 2006.

Guys liked the Gas Buster not so much because it supposedly helped cut down the extra gas blowback from running the M4 with a suppressor, but because it came with an oversized latch, making it easier to find and grab under pressure, especially with gloves on. To this day, the M4A1 is still issued with the pitifully small milspec charging handle latch.

The H&K steel magazine was not very popular in SF because it was too heavy. Fully loaded, the steel body mag weighed twice what a loaded aluminum one does. One might be able to justify carrying the extra weight on patrol if they were noticeably more reliable, but they were prone to denting if you dropped them on hard surfaces (especially rocky terrain), so many, myself included, did not see any advantage to using them.

TO BE CONTINUED …

During those early years in the War on Terror, the SOPMOD program proved a big hit, from the successful invasion of Afghanistan to the streets, alleyways, and close-quarters urban areas of Iraq. The M4A1 Carbine and SOPMOD items performed well, but there was room for improvement.

As the war carried on, operators desired even more performance out of the M4 and SOPMOD, leading to a complete second generation of SOPMOD optics and accessories.

In an upcoming issue of S.W.A.T. Magazine, I will cover the implementation of SOPMOD Block II and my experience with it during my time fighting in Afghanistan.

1 comment