The world that existed when Eugene Stoner conceived the AR-15 rifle is a much different world than we live in now. Not only have politics changed, but the way we fight wars has also changed.

In some cases, this change was evolutionary and methodical. In other cases, it was more drastic. For some organizations, using firearms to engage bad guys is one of those things that evolves at the speed of turtles. The reasons are many, but among them may be institutional inefficiency, “we have always done it this way” syndrome, “don’t rock the boat” mindset and other more frivolous nonsense.

The Charging Handle—correctly known as the Handle Assembly, Charging NSN 1005 00 017 9546 (part number 8448517), consists of the handle, a latch, a helical compression spring, and a pin.

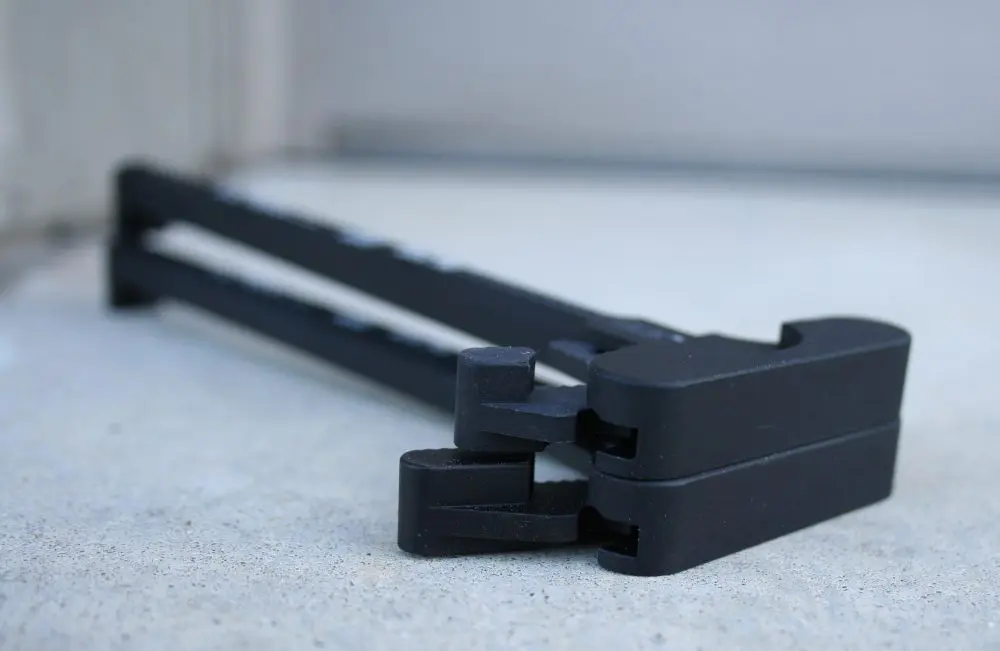

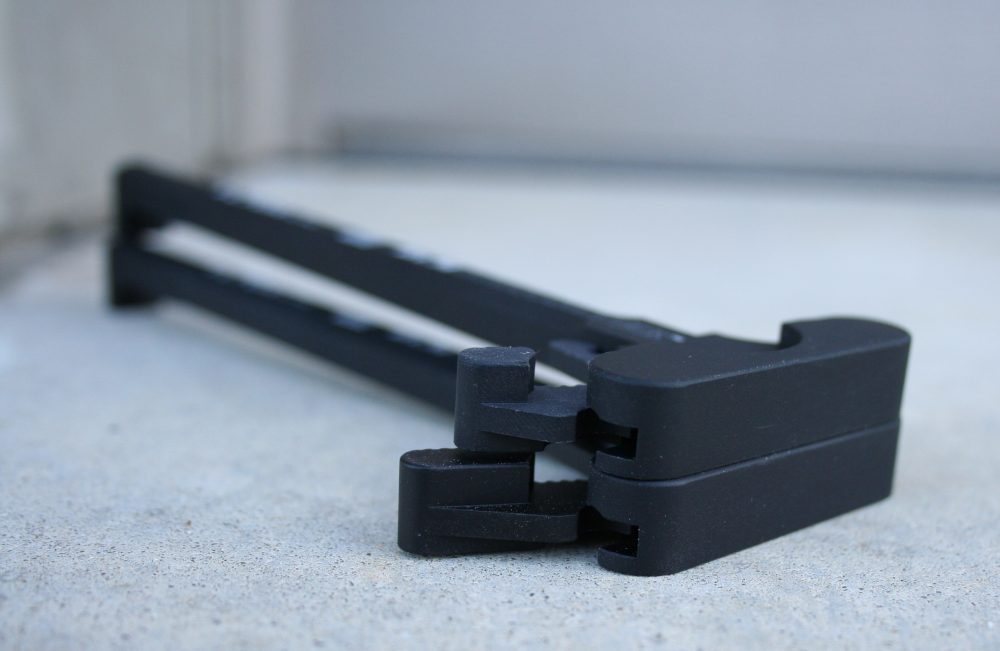

Aftermarket charging handle and extended latch. Note that shaft is bent—a show stopper as far as running your gun goes…

Contrary to popular belief, parts ain’t parts, no matter how much disinformation is passed down on the errornet.

The military Charging Handle (CH) is forged 7075 aluminum. Two other grades of CH exist: a lesser quality CH made from 6061 forged aluminum, and the lowest quality, a 6061 aluminum extrusion.

As required by contract, the mil quality CH is found on the Colt, FN and Sabre Defence guns. It may also be found on certain other guns, to include those built by Bravo Company Manufacturing.

Other makers will use the lesser quality parts to match their particular corporate attitude, culture and market. Let’s face it, the majority of the civilian AR market shoot their guns very little, if at all. Substituting a lower cost/lesser quality part may not be an issue for those who use their weapons for lesser applications.

As originally designed, the M16 was charged by the shooter (who is always right-hand dominant in the Operators Manuals) in this manner: remove the right hand from the firing grip, “rabbit ear” the charging handle by placing the trigger finger over the charging handle latch, social finger over the right side and pull the CH to the rear.

Even the highly regarded PRI Charging Handle Assembly can fail.

When we first received the M16s years ago, no one ever questioned this. After all, we did it this way on the M14, the M1, and my Dad operated the bolt of his Model 1903 and M1 with the strong hand. It was part of the “we have always done it this way” syndrome.

The issue at hand is that, Mom’s apple pie aside, our elders may have known something about shooting, but fighting with guns is a constantly evolving technique, and we have learned a thing or three as time and technology have progressed.

Using the strong (read “right”) hand to cycle the charging handle was probably done for two reasons. One was that the military had to train everyone to function regardless of age, IQ or number of teeth in the mouth. They therefore defaulted to the simplest method: using the dominant hand permitted more dexterity and therefore was more useful for the masses.

A secondary issue was that the marksmanship trainers were still locked onto the loop sling, and that immobilized the non-dominant arm. In other words, a technique that was useful for marksmanship, but seldom if never used in actual fighting, took precedence over a Tactic, Technique or Procedure (TTP) used for fighting.

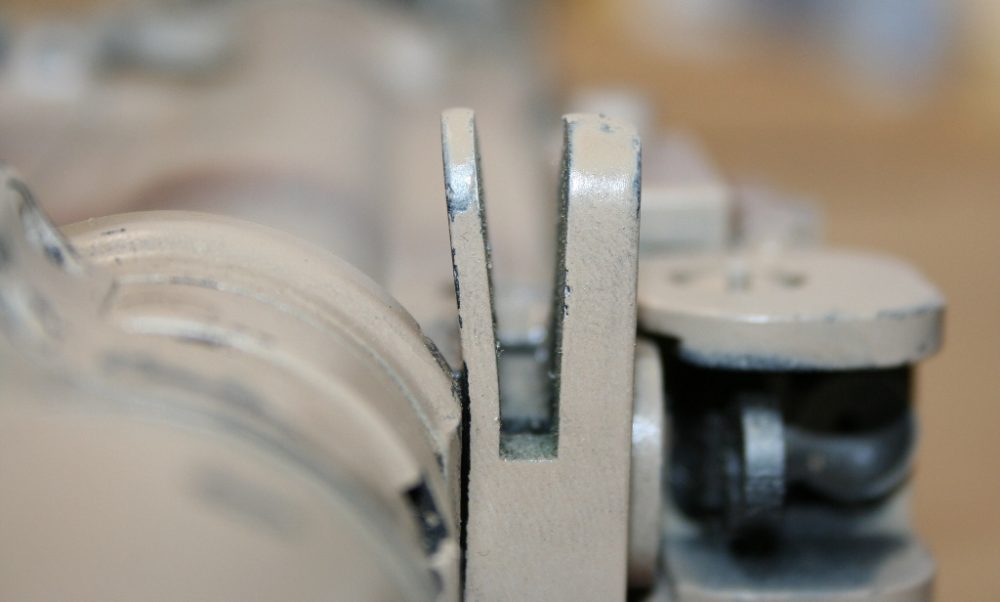

The widemouth. This occurs when asymmetrical pressure is introduced onto the pin. Eventually the pin will break or the CH will spread apart.

As time progressed, those who were clear thinkers developed better TTPs for fighting at close range. Among these were maintaining a master grip with the dominant hand.

Keeping that strong-side paw on the pistol grip and cycling the charging handle with your support-side hand means we can perform this task more efficiently, which translates into greater speed.

And how much time do you have in a gunfight? The answer is simple. You have the rest of your life to either sort out your issue before it sorts you out. That life may be long and profitable, or short and miserable if you don’t win the fight.

Generally, you would roll the carbine outboard (clockwise) while maintaining a master grip and shoulder contact with the carbine.

Using your support-side hand, you can access the CH latch either by making a claw of your support-side hand, or by using the palm/knife edge of the hand to cycle the CH.

This saves you some very precious time not only in cycling the action, but also in returning the carbine to the target.

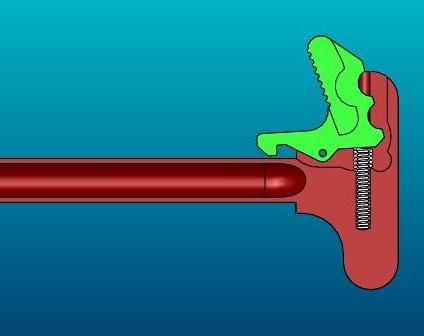

Drawing of MOD 3 from the bottom, showing it in closed position.

To make this technique easier, several companies made replacement latches (using the host helical spring and pin) that were larger and thus easier to manipulate. The Badger Latch is the most common, and larger, piece, and the PRI a smaller and significantly more expensive one, but considered useful for those running their guns suppressed.

This is actually easier done than said, once people make that paradigm shift to do something more efficiently.

As with the cycling of the action of any weapon, it must be done positively. Gently cycling the action or slide of any weapon is a surefire path to disaster, as the action will not always go home and the potential for inducing a malfunction is great.

Herein lies the problem. Eugene Stoner was absolutely brilliant and gave birth to the best service rifle this country has ever seen. But the state of the art of gunfighting as it existed in 1959 was significantly different than what we have experienced in the last 15 years. To that end, the charging handle, while strong (we are talking the CH made to the spec here) was made to be used by the rabbit ear method.

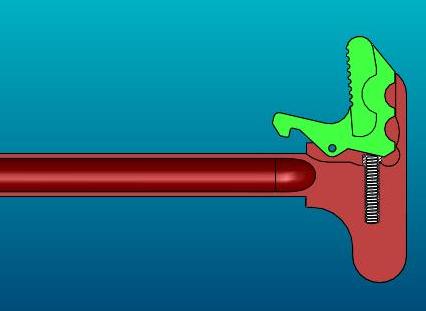

MOD 3 showing open position.

When charging with the support-side hand, several problems arise. One is that the movement is not straight to the rear as designed, but rather with the pressure to the right.

The first issue is that this pressure to the right may cause some charging handles to bend. Truthfully, we have never seen this happen with a CHA built to the milspec, but we have a box full of bent and broken CHAs that came from guns not built to a standard. That bend can be minor or major, but it can never be good.

The larger problem is with the pin. When that asymmetrical whack is delivered, all of the force is centered on the latch pin instead of on both sides of the CH itself. And while the made-to-spec pin may last longer, none were designed for this type of stress.

We have seen several CHA where not only did the pin fail, but the slot in the CH where the latch fits in was spread open, mimicking a wide open mouth.

We have seen even the highly regarded PRI aftermarket CH fail. We broke two of these in two days at a Memphis PD class. Wes Grant provided them and was as perplexed as we were. But we have seen this multiple other times as well. Nothing is perfect.

Mod 4 Gunfighter on an LWRCI M6A3 Carbine. Note that the back of the CH is completely closed off.

Paul Buffoni of Bravo Company MFG started looking into this awhile back and, though his ideas were dead on, some issues were difficult to resolve. That ended when Paul hooked up with Eric Kincel of Vltor. This joining of minds and ideas resulted in a new design for a charging handle and latch that puts the load onto the CH and not the pin. Vltor holds the patent and Bravo Company MFG, Inc. manufactures the BCMGunfighter™.

The BCMGunfighter is available in two models: P/N GFH Mod3 and P/N GFH Mod 4. The Mod 3 latch is similar in size to the ubiquitous Badger Tac Latch and the Mod 4 is analogous in size to the PRI latch.

The height of each latch is approximately 7/16″ high. The Mod 3 latch extends approximately 3/4″ from the charging handle, while the smaller Mod 4 extends about 3/8″. The BCMGunfighter is machined from 7075 T6 billet aluminum stock (Mil-A-8625F), with a Type 3 Class 2 seal (hard anodizing). The pins and springs are per the military spec.

To prevent damage/failure of the CH, the BCMGunfighter has backstops engineered into the extended latch and the charging handle. As the latch is opened up, its travel is limited by these flat surface backstops. This travel-limiting feature takes the stress off of the roll pin and transmits it into the body of the charging handle.

Gunfighter CH on top of a mil spec CH with a Badger Latch.

We have been running multiple BCMGunfighter CHAs in some of our T&E guns. Initially we had four, but now we have 21 fielded, including the LWRCI and BCM T&E guns. We kept the Colt 6940 as issued.

The transition from a conventional extended latch is seamless, as would be expected. We have been teaching support-hand operation of the CH for over 15 years now, so from our personal experience, this was simple. However, the advantage here is not something that might be seen in the short term, and perhaps it may never be seen.

It is hard to quantify something outside of the laboratory, and without sophisticated testing, the benefit of the BCMGunfighter™ Latch might also be hard to quantify. However, we have seen too many OEM charging handle assemblies with broken pins, bent shafts and spread mouths. The BCMGunfighter™ Latch is the first step we have seen in rectifying the problem, and it sure looks like it will be an improvement.

Some will question the addition of the Bravo Company MFG logo on the CH. The gun business—like banking, Oriental rugs, jewelry, furniture and other retail businesses—has a certain amount of ethical, professional people working hard. There are also a number of thieves of varying degrees.

Mod 4 (top) and the Mod 3 (bottom) showing the relative difference in size.

The purchasing public is also made up of some straight arrows, some crooks and a lot who will run a scam if they believe they can get away with it. To that end, some misguided souls have been purchasing what may be advertised as BCM bolt carrier groups from less than ethical sellers and returning them to BCM for refund/replacement.

Paul at BCM has since started marking his BCG, uppers and lowers and now the BCMGunfighter Charging Handle to prevent such shenanigans.

Paul is adamant that the BCMGunfighter Charging Handle is not for everyone, but may be extremely useful for those who embrace the idea that there may be a better way of killing bad guys.

If this seems like a lot of effort to put into something that has been around, basically unmodified, for almost 50 years, you are right. The simple addition of an extended latch was a start, and while it made it easier to manipulate the CH, the underlying problem of failure at the pin was still there. The Gunfighter latch addresses this, and reducing the potential for parts failure enhances the overall efficiency of the system.

Image from the Guidebook For Marines. This Marine was using the (then) approved rabbit ear method for manipulating the CH. The problems are obvious.

Fifteen years ago, there were relatively few choices in the AR world. That has changed, and with various companies debuting new AR offerings at the cyclic rate, we have choices.

Be a smart consumer and buy wisely.

[Pat Rogers is a retired Chief Warrant Officer of Marines and a retired NYPD Sergeant. Pat is the owner of E.A.G. Inc., which provides services to various governmental organizations. He can be reached at [email protected].]

SOURCE:

Bravo Company USA, Inc.

Dept. S.W.A.T.

P.O. Box 341

Hartland, WI 53029

(877) BRAVO CO

www.bravocompanyusa.com