Semi- and full-auto weapons function by means of different operation systems, covering the spectrum from recoil operated to electronic—and with a healthy dose of just about everything in between. For the purposes of this article, we’ll be looking at the AR platform, which was designed around a gas impingement system.

The expanding gas from the fired bullet goes down the gas tube and makes contact with the bolt-carrier gas key. The gas pushes the carrier back, which unlocks the bolt locking lugs, causing the action to cycle. For the weapon to function, all the parts need to work as designed. That means as specified and well maintained. For the AR, this means the gas tube needs to be functional, the bolt gas rings in good working order, and the boltcarrier gas key tight.

The gas tube is not normally a problem, but it can erode. It can also be damaged on the receiver end for a variety of reasons.

The bolt rings can be considered analogous to the piston rings on an internal combustion engine. They provide a seal between the bolt and bolt carrier, and will wear with time. To check for wear, remove the firing-pin retaining key, the firing pin, and the bolt cam pin. Hold the bolt carrier upside down. If the bolt stays within the carrier, you are good to go. If it falls out under its own weight, the rings are worn and need to be replaced.

Bolt rings are inexpensive and should be replaced regularly (instructions in the SOPMOD M4 Carbine Reliability Enhancement Kit suggest they should be replaced at every cleaning). A myth that has reached official proportions is that the rings must be misaligned. The Colt armorer instructors state that this is false, and the gun will run fine with a single (good) bolt ring. If misaligning the gas rings gives you a warm and fuzzy, have at it—but it adds absolutely nothing.

The bolt-carrier key needs to be correctly mated to the bolt carrier, with the screws properly tightened and staked to prevent them from loosening.

Herein lies the rub. Money drives business, and all companies look for ways to cut costs. Some of these practices can be along the order of improving efficiency. Other practices may include using lesserquality parts, or skipping steps in order to increase production.

We have seen a great number of bolt carriers with the key improperly staked (the so-called girly-man stake, wherein a limp wrist is used to “strike” the part) or not staked at all. In one class I conducted for a very competent state police tactical team, a request for M4 Carbines turned into the bean counters buying something “just as good” but that cost less. As with many organizations, they found out that “low bid” was not as cost effective as “best value” in that, of the guns purchased, approximately 25% had bolt carriers that were not staked at all. (These weren’t the only problems. Barrels were misaligned, some guns wouldn’t run on full auto, and the worst was the fact that customer service was nonexistent.) The agency was able to compare the bolts on their previously issued Colt M16s with those of the new guns, and the contrast was an eye opener. You can pay now, or you can pay later—but you are going to pay.

The problem with an unstaked or improperly staked bolt-carrier key is that eventually the two screws holding it to the carrier will loosen. No amount of torque or adhesive can be guaranteed to prevent this. Once those screws loosen, the gun will start leaking gas, and when that occurs, the rifle will start short stroking. And if that happens, you are out of business.

Any company is capable of making great guns. Any company is also capable of turning out something of poor quality. The keys here are in the consistency of the quality control and the frequency of problems.

In every open-enrollment class I teach, I find carrier keys that are not staked or improperly staked. I find this with all manufacturers, though the frequency of problems with any particular maker may be hard to pin down. This is because many students are degenerate tinkerers, and parts swapping may occur at the cyclic rate the rifle fires. A bolt from one maker may wind up in another maker’s gun. A lower from one company may have another maker’s upper on it and a gun-show bolt and bolt-carrier assembly riding within. The owner may not really know what he has, or he may not want to own up to making a bad choice by purchasing unknown parts.

The military-only classes generally don’t suffer boltcarrier key problems. Colt and FN, the two companies that supply the military with M16A2, A3 and A4 rifles and Colt only for M4 and M4A1 Carbines, are subject to strict quality control/quality assurance, and standards have to be met. That doesn’t mean they are perfect, or that something not meeting a standard can’t slip through. It is just that the frequency of problems is much less than with those who are not required to meet a standard. Let’s face it: If companies do not have to meet a standard, they may not, and may take all the shortcuts they can to save money.

TM 9-1005-319-23&P, Change 8, outlines the procedures that the military uses in staking the carrier key screws. But the consistency with which armorers, cobblers, and kitchen-table hobbyists handle staking is notable only for the inconsistency of their efforts.

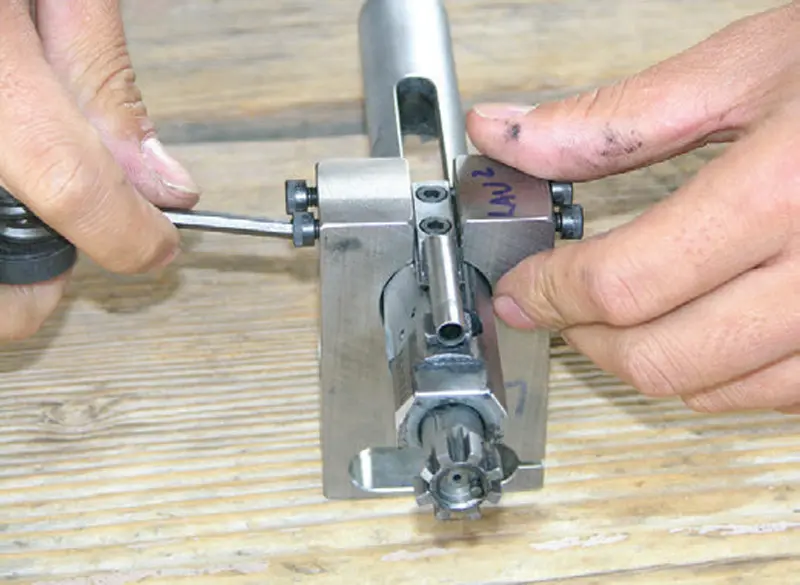

Enter Ned Christiansen, gunsmith extraordinaire, noted shooter, and genuine good guy. Frustrated by the poor staking on most aftermarket carrier keys (and as he states, some do not stake at all), he put his fertile brain into high gear and made a unit humbly called the Mother Of All Carrier Key Stakers, or MOACKS. Being a fan of consistency, Ned wanted something that would put a manly stake on each carrier key exactly the same way, every time. He wanted it to be simple to use and efficient in results.

The MOACKS is a substantial tool and, while compact in size, weighs in at 22 ounces of heat-treated 4140 steel. Ned wanted a tool that could function “as advertised” with minimal chance of screwing things up, and he succeeded admirably.

If your carrier key screws are already loose, remove them and clean them with a non-petroleum cleaner. Clean the mating surfaces of the bolt carrier and the gas key to make sure you have a good seal. Place some Red Loctite® on the screws and torque them to 50-58 inch pounds.

If the screws are tight, there is no need to remove them. Simply place the bolt carrier into the tool and line up the gas carrier key screws. Place a drop of oil on the tip of the screws. This will make the staking itself easier and will extend the life of the screws. Then tighten the four screws until they bottom out. The hardened tips will displace the carrier key metal over the screws.

While this staking will probably be sufficient (and is superior to most OEM staking), Ned suggests a counterstake. Using a Starrett automatic center punch, he places two stakes on each screw, just clockwise of the original stake. This may be overkill, but it follows the Nedster’s doctrine of being sure.

The MOACKS does more than just staking. Noting that some are concerned with the build-up of carbon on the bolt tail, Ned included a slot in the MOACKS to satisfy this urge. All you have to do is stick the bolt tail in and turn. Voilà! Carbon is removed.

From my perspective, I no longer remove that carbon as I am unconvinced it accomplishes anything except wasting time. My dislike for this stems from having autocratic 2111s in the armory refuse to accept a weapon with any “dirt” on it, and wanting it absolutely white-glove spotless when turned in. I believe the Marine Corps damaged more weapons with incessant and unnecessary cleaning than they ever wore out from shooting, and I cannot accept that the carbon on the bolt tail has any negative influence on anything. Having said that, if you want to remove carbon on the bolt tail, this is the best way to do it.

You can also remove the carbon that builds up on the firing pin flange by inserting it into a different hole in the tool made for this purpose. Neat!

The upgraded MOACKS Plus has all of the above plus a bolt-carrier bore reamer. This device removes the carbon that can build up inside the bolt carrier. The MOACKS acts as a handle, and the reamer stows within it, making for an efficient package.

Finally, there is a gas tube wrench accessory, a handy device that makes it easier to remove and install the gas tube.

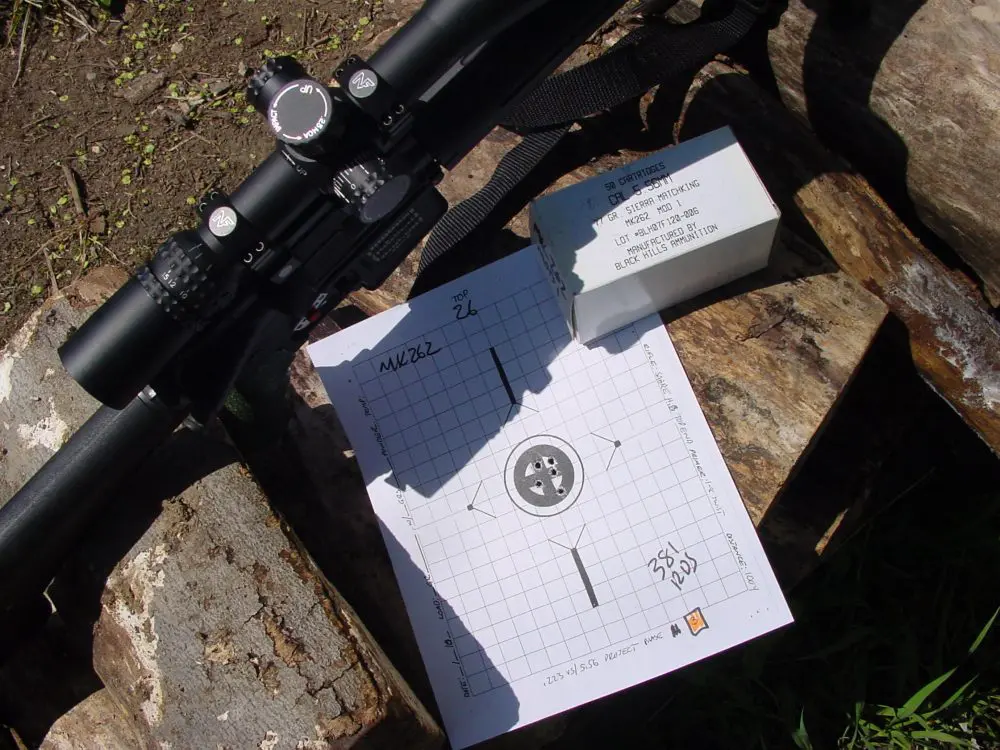

Ned also makes another very useful tool—a Neck and Throat 5.56 Reamer. Ned has observed that, while many makers mark their barrels as 5.56mm, the chambers are actually dimensionally closer to .223 SAMMI specs. While this is generally not a problem if you are shooting .223-caliber ammunition, it can be if you are shooting surplus or military-spec ammunition. Pressures can increase (especially during rapid-fire strings that you might be firing during training or operationally) and as a result primers may start popping. After leaving its (former) happy home, that primer needs to go someplace, and that often means into someplace that shuts the gun down. It is not pretty.

Ned’s reamer helps cure this issue. Disassemble the upper and apply some oil to the reamer. Insert the reamer into the chamber and turn clockwise. A nylon bushing centers the reamer in the receiver; the reamer itself is self-regulating. It is made so it cannot cut the shoulder and change headspace. When it bottoms out on the shoulder, it will spin freely.

Are chrome-lined chambers all 5.56? In Ned’s experience, Colt chambers are 5.56, but he considers anything else suspect. The chamber has a very thin layer of chrome and, while chrome is tough, Ned’s reamer has the benefit of a secondary heat-treating process (titanium carbo-nitrade) that can cut through the chrome lining of an under-spec chamber.

Understand that the purpose of a chrome chamber/ barrel is to reduce the effects of corrosion. But if you have an out-of-spec chamber, you are left with two choices: keep the chamber intact and put up with the ongoing malfunctions, or cut it to the proper specs and upgrade your weapons maintenance schedule.

Of course, buying something made to spec out of the gate would solve a lot of your problems to start with.

Several years ago, I had a husband-and-wife team attend a carbine class. They were accomplished pistol shooters but had no carbine experience. They bought two aftermarket carbines with consecutive serial numbers after seeing this model highlighted in a magazine. During the course his carbine worked, while hers didn’t. When her carbine got hot, it would not extract the fired case from the non-chrome-lined “match” chamber, and she finished the course with my carbine.

She contacted the maker, who told her that “everyone” wants match chambers because they make for a more “accurate” gun. After much gnashing of teeth, they agreed to replace the barrel with their new “M4” wannabe barrel, although like the previous tube, it was not chrome lined and had that pesky “match” chamber. At the next carbine class, the exact same thing happened. A “match” chamber in a carbine barrel may make for better intrinsic (though not practical) accuracy, but it’s often at the cost of reliability.

While trying to sort out these problems again, the bolt cracked at the cam pin hole (coincidentally, the bolt on her husband’s gun broke at the same place on the very next day). She once again finished the class with my Colt carbine (one of 14 students who used that particular carbine over the years after theirs went down). While the maker claimed ammunition was the problem, none of the other students, using the same lot of ammunition, had any problems.

“Parts is parts” was a line from a chicken commercial, but it makes no more sense for chickens than it does for ARs. If you believe that all parts are the same, I have a bridge that spans the East River I can let you have for a song. Ned’s Neck and Shoulder Reamer can make up for a manufacturer’s fixation on “match” grade chambers, but it cannot compensate for bolts that don’t meet a standard.

When you choose to purchase a carbine, understand your requirements and make the purchase based on those criteria. If you want reliability, travel down that road. If accepting mediocrity is your thing, then you can accept “just as good as.” The decision is yours.

The MOACKS and the Neck and Throat 5.56 Reamer are simple to use and precise in execution. They may not fall into the “must have” kit for an individual, but do for those with multiple weapons (especially from different makers) and armorers.

I carry a MOACKS in my gear box, and I’m not sure how I got along all these years without it.